AI implementation

7 Job-ready AI Applications in Construction

15 min read

—

Nov 29, 2021

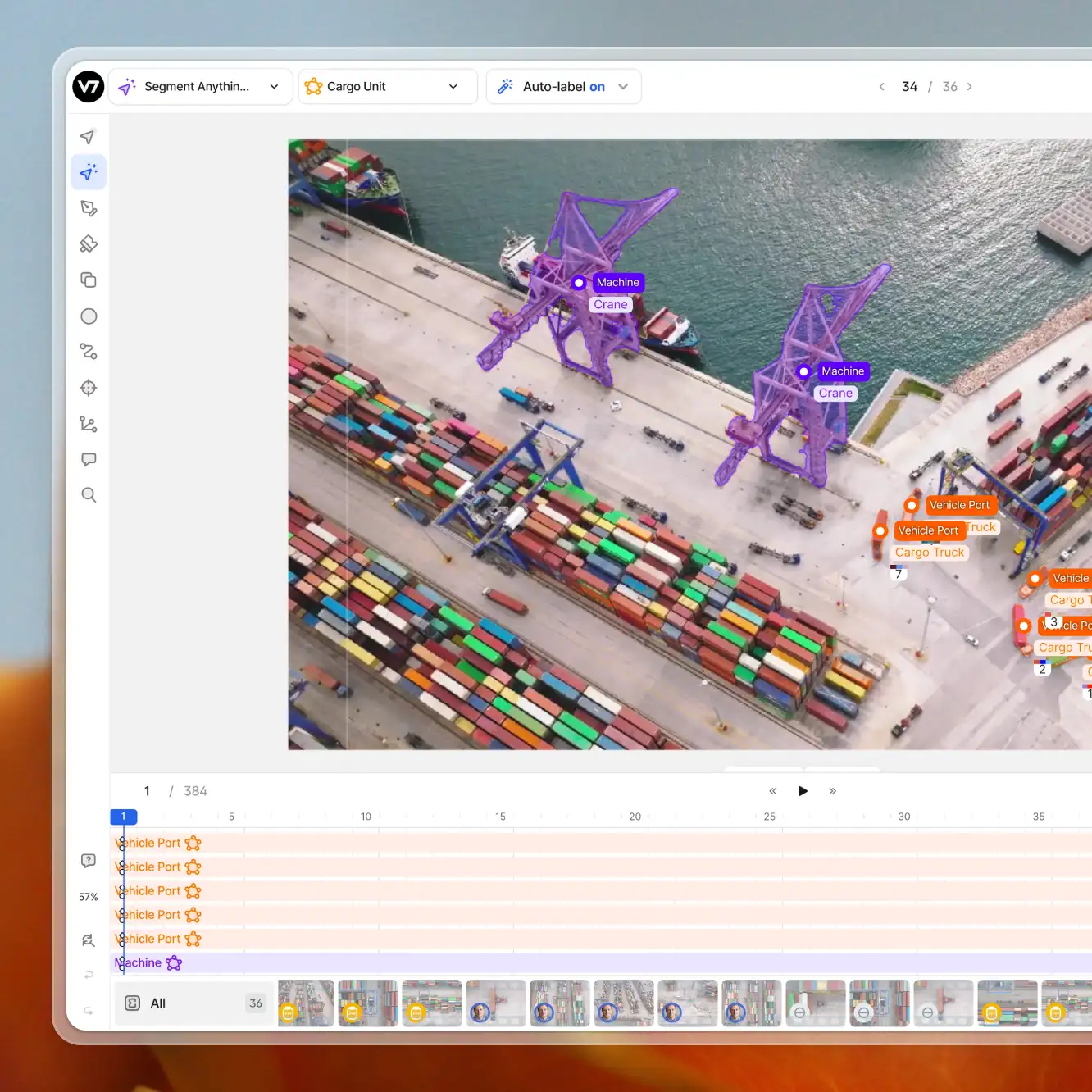

How do smart construction companies leverage the power of AI? Learn about the most prominent computer vision and machine learning use cases and explore how top companies use V7 to build AI solutions transforming the construction industry.

Alberto Rizzoli

Co-founder & CEO

Traditionally, managing a construction project has depended on human knowledge and experience.

And this works, but—

It leaves some serious gaps in efficiency and consistency.

As a result, modern issues such as labor shortages, increasing government investment, and cost-cutting demands have motivated the adoption of AI to help out.

Computer vision and machine learning can provide project managers with incredibly valuable data and construction analytics for making projects more time, labor, and cost-efficient.

And the benefits aren’t just theoretical.

In this article, we’ll examine seven of the current most significant applications of AI in construction. In particular, we’ll see how deep learning architectures have been applied for solving image classification, object detection, object tracking, and activity recognition challenges.

Here’s what we’ll cover:

PPE detection

Workplace hazard detection

Corrosion detection

Infrastructure asset inspection

Predictive maintenance

Labor efficiency monitoring

Land survey and mapping

Have a look at this graphic to get a sense of the key deep learning tasks and their application in the construction industry context.

Ready to streamline AI product deployment right away? Check out:

Personal Protective Equipment (PPE) detection

Here’s the harsh truth—

PPE can save lives... but only if people actually use it.

According to NIOSH, there are 2,000 work-related injuries every day in the US that could be prevented through proper use of PPE.

Construction managers only have two eyes and a finite amount of time, so it can be tough to make sure everyone is using appropriate protective equipment. But this is where computer vision techniques such as object detection can make a big difference.

Check out YOLO Object Detection Guide.

Deep learning has made it possible to reliably detect a wide variety of protective equipment, from hard hats to safety goggles, gloves, high visibility jackets, and ear protectors. And with more training, the capacity for AI to identify safety equipment – or its absence – will only grow.

This means that job site cameras can act as additional eyes to help construction management ensure the safety of their employees.

A good example of construction safety software in action comes from this study, in which a new computer vision system was developed to detect construction workers’ posture and PPE in real-time. The system was trained with a dataset of 95 videos from the construction site cameras and learned to detect eight different kinds of PPE and nine different types of posture.

When tested on new video data, the model showed a lot of promise, achieving high-performance results in both identification and recall ratios over 83 and 95%, respectively.

Workplace hazard detection

While monitoring PPE compliance can significantly improve workplace safety at a construction site, it can’t ensure workers’ safety all the time. Looking out for workplace hazards themselves is another area that can benefit from support in the construction industry.

According to the Health and Safety Executive in the UK, a total of 142 workers were killed on the job in 2019/2020 and 693,000 sustained an injury at work. Further, the Labour Force Survey estimates that the cost of injury and ill health due to construction site working conditions was £16.2 billion in 2018/2019.

Clearly, keeping construction workers safe is a big job with serious stakes. But once again—

AI is here to help!

AI-based computer vision solutions have been developed that can track, predict, and prevent workplace accidents from happening. Yes, this seems like a tall order, but here’s how it works:

Techniques such as object tracking can be used to identify construction workplace hazards like flammable materials or to monitor employees in hazardous zones. The AI models can then provide real-time warnings to managers and workers on-site.

Platforms such as IRIS are a great example of how this works in practice. They’re already leveraging AI integration to accomplish their mission of “zero accidents at workplaces”.

IRIS’s AI creates a virtual map and analyzes the entire working area using CCTV camera feeds. It’s then able to identify hazards and configure real-time notifications and alarms on WhatsApp, SMS, buzzers, or PA systems any time a workplace hazard poses a threat to a worker.

For example, using object detection models, where the objects are annotated using bounding boxes, IRIS can identify forklifts and observe their movement in a given area. The models then raise an alarm if a forklift is moving too fast, going in the wrong direction, or parked in the wrong place.

Looking for the perfect bounding box tool? Check out 9 Essential Features for a Bounding Box Annotation Tool.

AI models can also identify fires earlier than traditional detection systems, and even determine how many people are in danger and their locations.

But computer vision can do more than just detect external hazards.

Construction workers can easily injure themselves with improper lifting or other manual handling procedures. AI models can use techniques such as human pose estimation to monitor worker posture and pose, raising warnings if workers are at risk of injuring themselves.

IRIS isn’t the only construction safety AI in town, though.

Everguard complements computer vision with wearable technology and sensor fusion to improve worker safety with PPE detection, fall detection, forklift safety, anti-collision, crane detection, and posture detection.

If all this AI supervision sounds rather intrusive, consider one of V7’s users, IntenseEye. Their AI models also monitor the workplace and detect employee health and safety incidents, but they prioritize privacy as well as safety.

IntenseEye’s visual data is processed and then deleted so that they don’t store any personal information. And their algorithm uses body features to identify human “objects” instead of facial recognition. In fact, their AI models are even designed to ensure anonymity by blurring the faces of workers in output data.

So, there is no need to fear that Big Brother is watching over the workplace. Safety is job #1 for this AI.

Corrosion detection

Keeping construction workers safe through PPE and workplace hazard monitoring is just one of the ways that AI can make job sites safer and more efficient.

AI techniques like image classification and object detection can also be used to detect corrosion, which is a serious threat to construction operations and human safety.

Failing to identify corrosion can lead to machines and structures breaking down, leading to higher maintenance costs, environmental damage, injuries, and even lost lives.

Currently, certified inspectors tour construction sites to look for corrosion. But because this method relies on human judgement, the results are often inconsistent, subjective, and prone to error. With so much at stake, consistent, objective detection of corrosion can be a game changer for job site managers.

As you might expect with tasks involving visual inspection, AI and ML have some solutions to offer.

To this end, companies like Infosys are already developing neural network-based AI solutions to reliably and consistently find and classify corrosion.

But can AI really detect such small, gradual processes?

Yes!

First, the algorithm uses binary classification to identify different kinds of corrosion. Two important distinctions are between coating loss (when the protective coating on a metal like steel begins to break down) and actual rust.

Next, it performs multiclass severity classification to determine the severity of corrosion.

Infosys trained its algorithm with a 70% test-train split on a data set that they labeled to create 3,000 annotations. They then used four annotation classes to differentiate levels of coating loss severity: P1, P2, P3, and normal.

Even with this relatively small data set, Infosys was able to train their model to identify and classify coating loss with 70% accuracy!

Looking for the perfect image annotation tool? Check out our list of the 13 Best Image Annotation Tools

Infosys also notes that with training on more visual data, the algorithm’s accuracy will only improve. This points to the importance of collecting large sets of relevant data, which is, fortunately, an easy task. In this case, training images can be captured by simply snapping photos of corrosion with a digital camera or drone.

Infrastructure asset inspection

Moving on from safety, AI computer vision is also being developed to inspect infrastructure assets on construction sites.

As with corrosion detection, this kind of inspection traditionally depends on human observation and judgment. While subjective human assessment can certainly work, it also has a tendency to be inconsistent and unreliable, which wastes time and resources.

Computer vision systems, on the other hand, can support human inspectors in making more objective assessments.

Remote monitoring of job sites allows for more real-time, up-to-date construction tracking data on infrastructure assets and helps construction managers keep on target with the building information model (BIM) schedule.

These AI systems not only track the progress of a construction project as a whole, but can also identify individual assets and track user information, maintenance requirements, and physical location as well.

This is a powerful feature, because if any specific part of a construction project is experiencing cracks, concrete spalling, leakages, or other types of damage, object detection algorithms will find the problem and inform asset inspectors and construction managers immediately.

So what does this look like on the job?

Pipeline Inspection

Researchers in this study used Deep Neural Networks to automate the detection and classification of pipeline external damage.

Remotely operated vehicles (ROVs) and drones captured survey videos of the pipeline, which researchers then broke down into frames with optical character recognition (OCR)-extracted time/location stamps. Pipeline inspectors then helped annotate these images to precisely mark and categorize damaged areas and their boundaries.

Once a deep convolutional neural network architecture was trained on all this data, it was deployed to do its own test inspections.

And the results did not disappoint.

The AI model managed an average precision of 86%. While not perfect, this is on par with the performance of human inspectors, only much faster.

You can use V7 for your OCR projects. Take advantage of our public Text Scanner model to perform any OCR tasks.

Defect Detection in Concrete

Very small cracks, leaks, and dents in concrete structures can cause big problems later on if left untreated. Think about how freezing water can turn small cracks in a street into massive potholes.

Computer vision systems combined with camera and drone technology are amazingly well suited to identifying and reporting these types of defects. Techniques such as object detection, image classification, and image segmentation can be used to detect and measure defects in as small as 0.01% of an image.

Using these techniques on images of buildings, bridges, roads, pipes, or tunnels can help construction managers make building and maintenance more efficient by predicting future conditions, supporting investment planning, and allocating targeted maintenance and repair resources.

For example, in this study researchers investigated how well unmanned aerial vehicles (UAVs) and deep learning could inspect concrete structures. They used 3,000 images from a massive data set of publicly available images, and divided them into two categories of “crack” and “no crack”.

The proposed “AlexNet” CNN algorithm was then trained on 1,050 images and tested on 450 images. Amazingly, even with images that included noisy backgrounds, such as cracks with shadows and stains or cracks on rusty and rough surfaces, the algorithm achieved 98.4 % accuracy in crack detection!

Even More Infrastructure to Inspect

Similar technology and techniques are also being used for infrastructure inspection outside of construction sites.

For example, the company Eye For Infrastructure uses its AI models to analyze the quality and deterioration of roads. These kinds of systems can also be used to monitor the infrastructure by detecting damaged structures, tree overgrowth, drainage problems, and downed power lines.

Currently, AI computer vision models are helping inspect a wide range of infrastructure from tunnels to bridges, solar farms, cell towers, and hydroelectric dams.

Without these kinds of utilities in good working order, we’d all be in a world of hurt. So having AI assistance to make inspection and maintenance more efficient helps us all!

Predictive maintenance

Human health and safety on a construction project is of utmost importance, but maintaining the “health” of on-site equipment is another critical task for construction managers.

According to a study by McKinsey:

Predictive maintenance can reduce machine downtime by 30-50% and increase its lifespan by 20-40%.

Replacing construction equipment is costly, and machines that aren’t functioning further cost a project time and money. Predictive maintenance aims to avoid these two issues by assessing the condition of equipment, which allows for maintenance before a problem occurs that may interrupt work.

The earlier a defect or issue is detected, the better the chance that it can be resolved before causing bigger problems.

As with other issues in construction, humans are capable of performing inspections and detecting issues, but they can’t accomplish this reliably 24/7.

Luckily, AI and machine learning can.

When machine learning systems are trained on large amounts of historical data, they can begin to predict when and what kind of maintenance will be necessary for a given set of equipment.

Read An Introductory Guide to Quality Training Data for Machine Learning.

Pairing this with the Internet of Things (IoT) sensors not only helps an AI model detect defects more accurately, but also provides additional training for better predictions.

It’s not all just a matter of observing the equipment, though. Machine learning models make their predictions using classification and regression models. Classification models can help predict the possibility that a machine will break down after a certain number of steps (actions or uses). Regression models can generate predictions on how much time is left before equipment maintenance is needed.

Since properly functioning equipment is central to making progress on a construction project, being able to predict when it will need maintenance helps solve business problems and streamline decision-making.

Explore how AI is used in predictive maintenance in manufacturing.

Of course, construction managers are still the ones who will check this data and make the decisions, but consistent, data-driven predictions will only help them do this better.

Labor efficiency monitoring

Measuring labor efficiency is a complex process.

Current methods are costly, time-consuming, and require significant labor themselves. And ultimately, the results are not all that reliable.

For example, it’s hard enough to track and measure the productivity of one worker, but when teams cooperate to accomplish a task, the assessment of productivity becomes all the more convoluted.

As a result, construction managers tend to assess labor efficiency only when a noticeable problem arises. So in general, there are many, many opportunities for improved efficiency that are entirely neglected.

Ai-powered computer vision, however, can make this job a whole lot easier.

Construction sites usually have several cameras installed to monitor the area. When these cameras are coupled with computer vision systems, they are capable of monitoring worker activity using techniques like object detection and human pose estimation.

Still, it’s not a simple task. Background clutter, occlusions, and uniformed workers who look similar to each other can make tracking difficult.

Nevertheless, researchers in this case study decided to give it a go. They proposed a framework in which labor productivity of construction workers could be measured by tracking their trajectory using on-site cameras.

Computer vision algorithms then process this data, tracking worker location over time and generating a 4D trajectory that can be converted into productivity data.

While working in 4D may sound a bit sci-fi, the framework turned out to be quite successful when tested on real-life data. When observing and assessing single and multiple workers on the job, the framework managed to determine worker time-on-task with 95% accuracy!

Looking for quality data? Check out 20+ Open Source Computer Vision Datasets.

Similarly, another paper describes how computer vision models can extract 3D worker trajectories from visual data and use a clustering-based method to generate work cycles that represent labor input.

When tested, this method was able to determine time-on-task in a construction project with 84% accuracy. Sure, improvements can be made, but considering humans’ limited ability to track time-on-task across an entire job site for multiple workers, the numbers are looking pretty good!

Land survey and mapping

So fa,r we’ve looked at how AI can help track, measure, and inspect the people and things inside a construction site.

But what about surveying the work site itself?

Getting an accurate lay of the land is crucial to a successful construction project—not only for better pre-construction planning but also for ensuring that construction is going according to plan.

To help with this, companies like Datumate do land surveys and mapping using AI-powered drone and camera technology.

A good example of this is their product DatuFly.

DatuFly captures images of land, construction sites, and infrastructure and then uploads them to a secure server. Next, the computer vision and photogrammetry algorithms convert the images into accurate, georeferenced 2D and 3D maps and models.

Of course, land surveying is something humans have done for centuries, and can do pretty well. But the modern accessibility of UAVs and computer vision techniques can make this process a whole lot easier by reducing the time needed and increasing accuracy.

AI in construction planning represents a major benefit to project managers and workers because faster, more accurate mapping means more efficient construction processes.

Building the Future with AI

Construction managers have a full plate when it comes to overseeing a building project. But from increasing job site safety to asset inspection and productivity measurements, AI/ML-powered computer vision can make overseeing such a complex task much easier, faster, and more accurate.

When the use of AI in construction can be leveraged to support planning and decision making, decrease project costs, and save worker lives, everyone wins.

And with more data and training, smart computer vision technologies stand to continue transforming the efficiency and safety of the whole construction industry.

Curious to learn more? Check out 27+ Most Popular Computer Vision Applications and Use Cases

Interested in learning how computer vision can support your construction projects?

Schedule a demo with our team at V7 to get started!

Check out next: