Annotation suite

Annotation suite

Data labeling for Frontier Models.

Lightning-fast, expert-driven.

Data labeling for Frontier Models.

Lightning-fast, expert-driven.

Customers

Customers

Build breakthrough AI models.

Join leading AI research labs and Fortune 100s.

Customers

Customers

Customers

Annotation suite

Annotation suite

Annotation suite

Create ground truth 10x faster without errors.

Manage expert labelers with AI-assisted annotation and review.

Demo

Demo

Demo

See it in action

Build in a visual, no-code environment

See it in action

Build in a visual, no-code environment

See it in action

Build in a visual, no-code environment

Dataset

Consensus

Logic

Complete

Dataset

5

Rail Maintenance

6

Files

4

Completed

2

In progress

66.67%

darwin.v7labs.com

Dataset

Consensus

Logic

Complete

Dataset

5

Rail Maintenance

6

Files

4

Completed

2

In progress

66.67%

darwin.v7labs.com

Dataset

Consensus

Logic

Complete

Dataset

5

Rail Maintenance

6

Files

4

Completed

2

In progress

66.67%

Suited for every industry.

Create your custom workflow.

RLHF + RLAIF

RLHF + RLAIF

RLHF + RLAIF

Dataset

Dataset

Review

Review

Logic

Logic

Annotate

Annotate

Complete

Complete

Model-in-the-loop

Model-in-the-loop

Model-in-the-loop

Dataset

Dataset

Model

Model

Annotate

Annotate

Review

Review

Complete

Complete

Webhook

Webhook

Webhook

Dataset

Dataset

Annotate

Annotate

Review

Review

Webhook

Webhook

"Visibility on metrics in V7 is very helpful to us, and it's something we didn’t have in our internal solution."

Andrew Achkar

Technical Director at Miovison

"Visibility on metrics in V7 is very helpful to us, and it's something we didn’t have in our internal solution."

Andrew Achkar

Technical Director at Miovison

"Visibility on metrics in V7 is very helpful to us, and it's something we didn’t have in our internal solution."

Andrew Achkar

Technical Director at Miovison

Automated labeling

Automated labeling

Automated labeling

Annotate any dataset

with speed and accuracy

Annotate any dataset

with speed and accuracy

Annotate any dataset

with speed and accuracy

For many AI teams, creating high-quality training datasets is their biggest bottleneck. Annotation projects often stretch over months, consuming thousands of hours of meticulous work. V7 can speed up data annotation 10x, turning a months-long process into weeks.

Use intuitive interface and AI-assisted tools to turn complex labeling tasks into a few simple clicks and adjustments. Work with any size dataset and file type, from videos, PDFs, and architectural drawings to specialized medical formats like SVS or DICOM.

AI-assisted data labeling

Label data at lightning speed with V7 Auto-Annotate and SAM2. Segment complex objects like lesions in CT scans and items on assembly lines with high accuracy. Achieve expert level segmentation across diverse domains, regardless of industry.

AI-assisted data labeling

Label data at lightning speed with V7 Auto-Annotate and SAM2. Segment complex objects like lesions in CT scans and items on assembly lines with high accuracy. Achieve expert level segmentation across diverse domains, regardless of industry.

AI-assisted data labeling

Label data at lightning speed with V7 Auto-Annotate and SAM2. Segment complex objects like lesions in CT scans and items on assembly lines with high accuracy. Achieve expert level segmentation across diverse domains, regardless of industry.

Auto-track for video

Track objects across selected time ranges in videos. Automatically follow instances and mark in-and-out of view situations. Streamline video annotation for tasks like AI-assisted surgeries, retail shrinkage prevention, or sports analytics.

Auto-track for video

Track objects across selected time ranges in videos. Automatically follow instances and mark in-and-out of view situations. Streamline video annotation for tasks like AI-assisted surgeries, retail shrinkage prevention, or sports analytics.

Auto-track for video

Track objects across selected time ranges in videos. Automatically follow instances and mark in-and-out of view situations. Streamline video annotation for tasks like AI-assisted surgeries, retail shrinkage prevention, or sports analytics.

Label similar objects

Pick one object and find similar ones automatically. Speed up repetitive annotation problems like preparing training data for cell counting models or product identification on shelves. Reduce manual effort in large-scale labeling projects. Reduce human errors caused by fatigue and monotony.

Label similar objects

Pick one object and find similar ones automatically. Speed up repetitive annotation problems like preparing training data for cell counting models or product identification on shelves. Reduce manual effort in large-scale labeling projects. Reduce human errors caused by fatigue and monotony.

Label similar objects

Pick one object and find similar ones automatically. Speed up repetitive annotation problems like preparing training data for cell counting models or product identification on shelves. Reduce manual effort in large-scale labeling projects. Reduce human errors caused by fatigue and monotony.

Model in the loop

Integrate external or out-of-the-box models to pre-label your data or detect quality issues. Compare performance between human labelers and AI models in blind tests. Connect models to your ML pipeline and improve your annotation process and model accuracy.

Model in the loop

Integrate external or out-of-the-box models to pre-label your data or detect quality issues. Compare performance between human labelers and AI models in blind tests. Connect models to your ML pipeline and improve your annotation process and model accuracy.

Model in the loop

Integrate external or out-of-the-box models to pre-label your data or detect quality issues. Compare performance between human labelers and AI models in blind tests. Connect models to your ML pipeline and improve your annotation process and model accuracy.

Use cases

Use cases

Use cases

Create high-quality training data.

V7 supports all your labeling needs.

Images

Videos

DICOM & NIfTI

Microscopy

RLHF

Speed up complex annotation tasks with AI-assisted labeling and custom computer vision models. Generate semantic pixel masks and segment irregular shapes with a single click. Use keypoints, brushes, polylines, and more.

Images

Videos

DICOM & NIfTI

Microscopy

RLHF

Speed up complex annotation tasks with AI-assisted labeling and custom computer vision models. Generate semantic pixel masks and segment irregular shapes with a single click. Use keypoints, brushes, polylines, and more.

Images

Videos

DICOM & NIfTI

Microscopy

RLHF

Speed up complex annotation tasks with AI-assisted labeling and custom computer vision models. Generate semantic pixel masks and segment irregular shapes with a single click. Use keypoints, brushes, polylines, and more.

In numbers

In numbers

In numbers

Faster annotation

Faster annotation

Faster annotation

Data types supported

Data types supported

Data types supported

Platform Uptime

Platform Uptime

Platform Uptime

Workflows

Workflows

Workflows

Leverage humans in the loop.

Build better ML pipelines.

Leverage humans in the loop. Build better ML pipelines.

Leverage humans in the loop.

Build better ML pipelines.

As annotation projects scale, AI teams struggle to track progress, maintain QA standards, and ensure accountability. Inconsistencies can quickly compound, leading to compromised data quality—which impacts the entire AI development lifecycle.

V7 allows you to design multi-stage review workflows to orchestrate your labeling process. Assign roles, tasks, and manage project completion. Use conditional logic and automations to always route data to the right stages or team members.

Collaborate

Improve teamwork with real-time collaboration features. Ensure smooth communication between annotators, reviewers, and ML engineers to speed up assignments. Delegate tasks and track progress of multiple independent annotation projects.

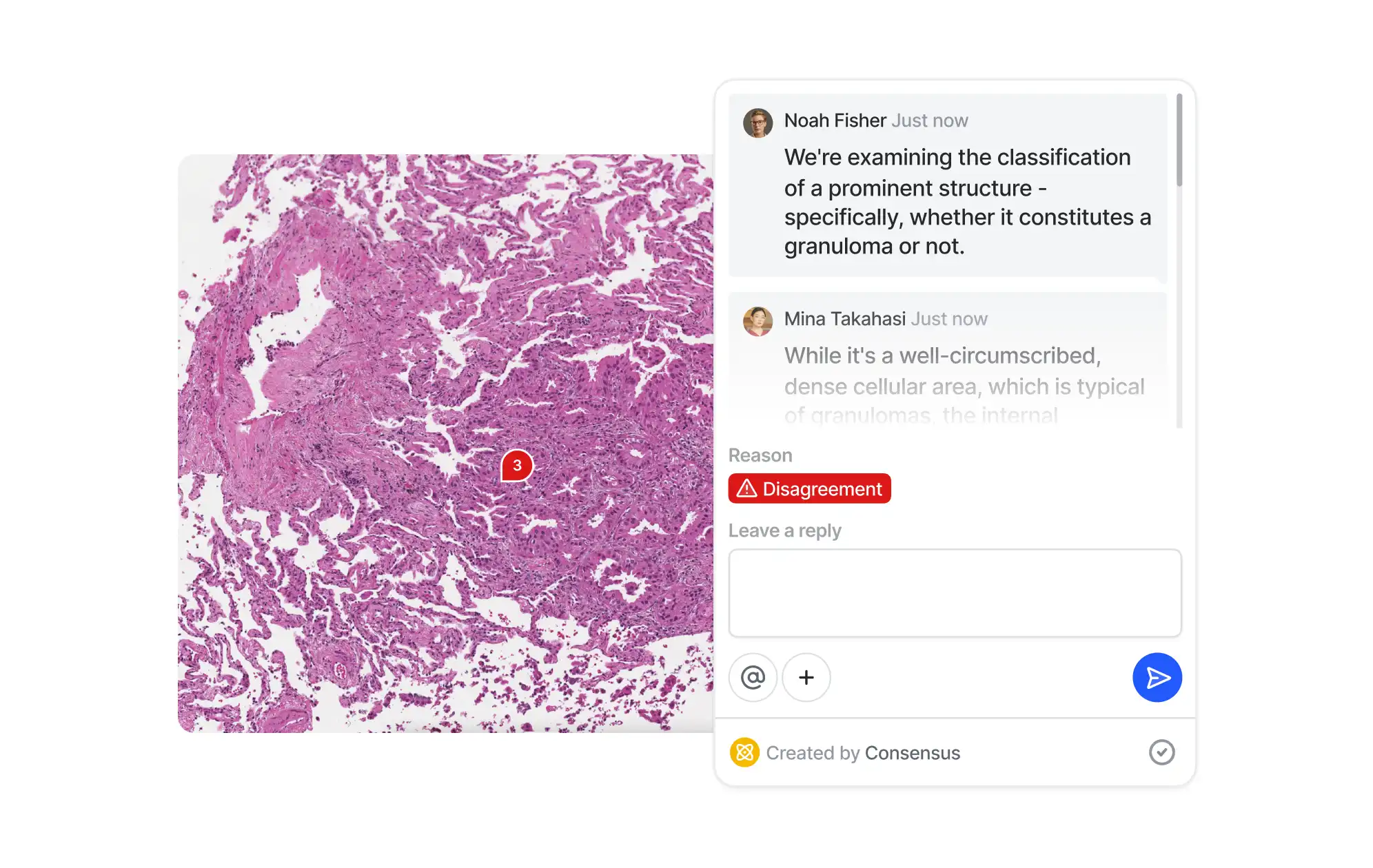

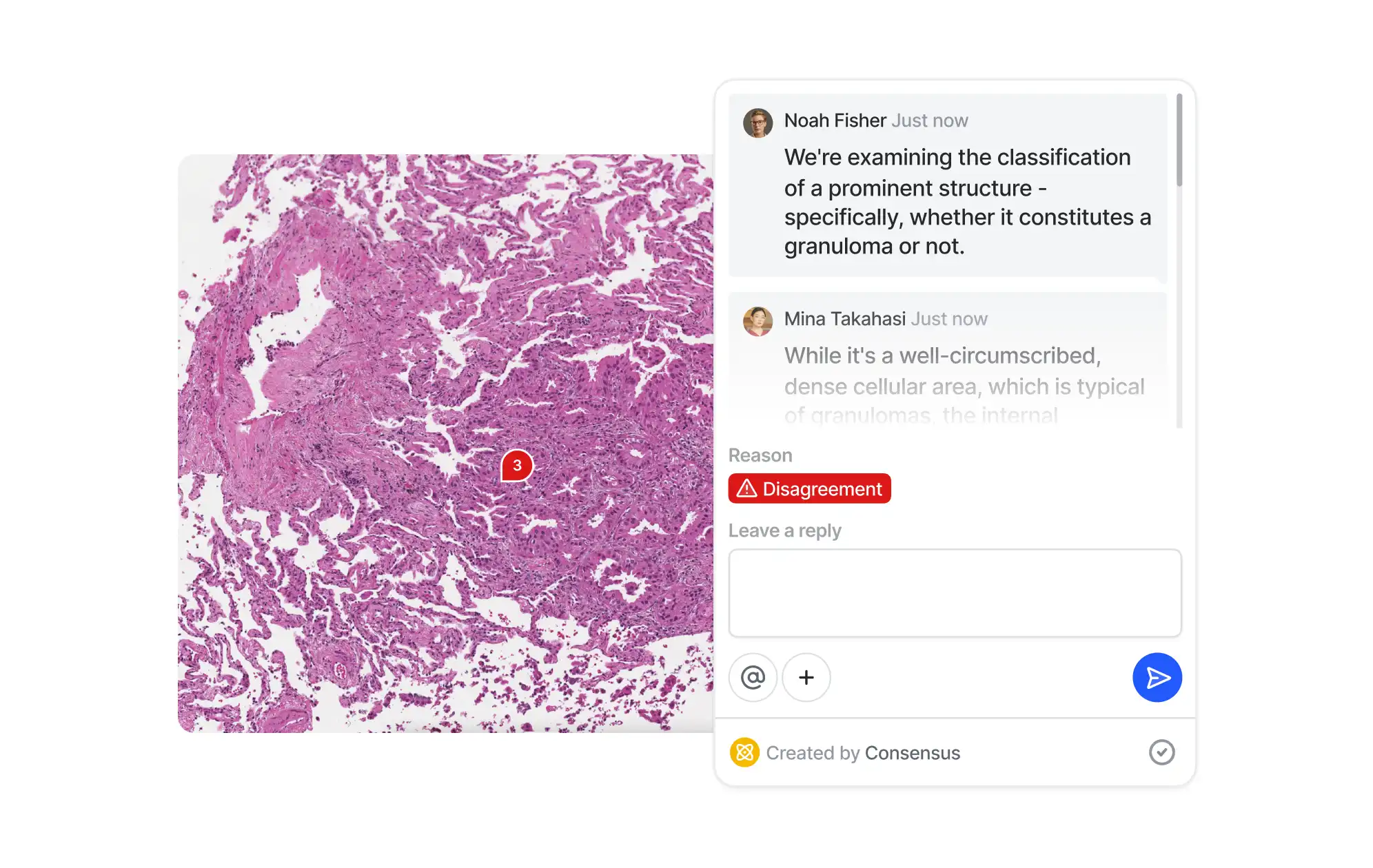

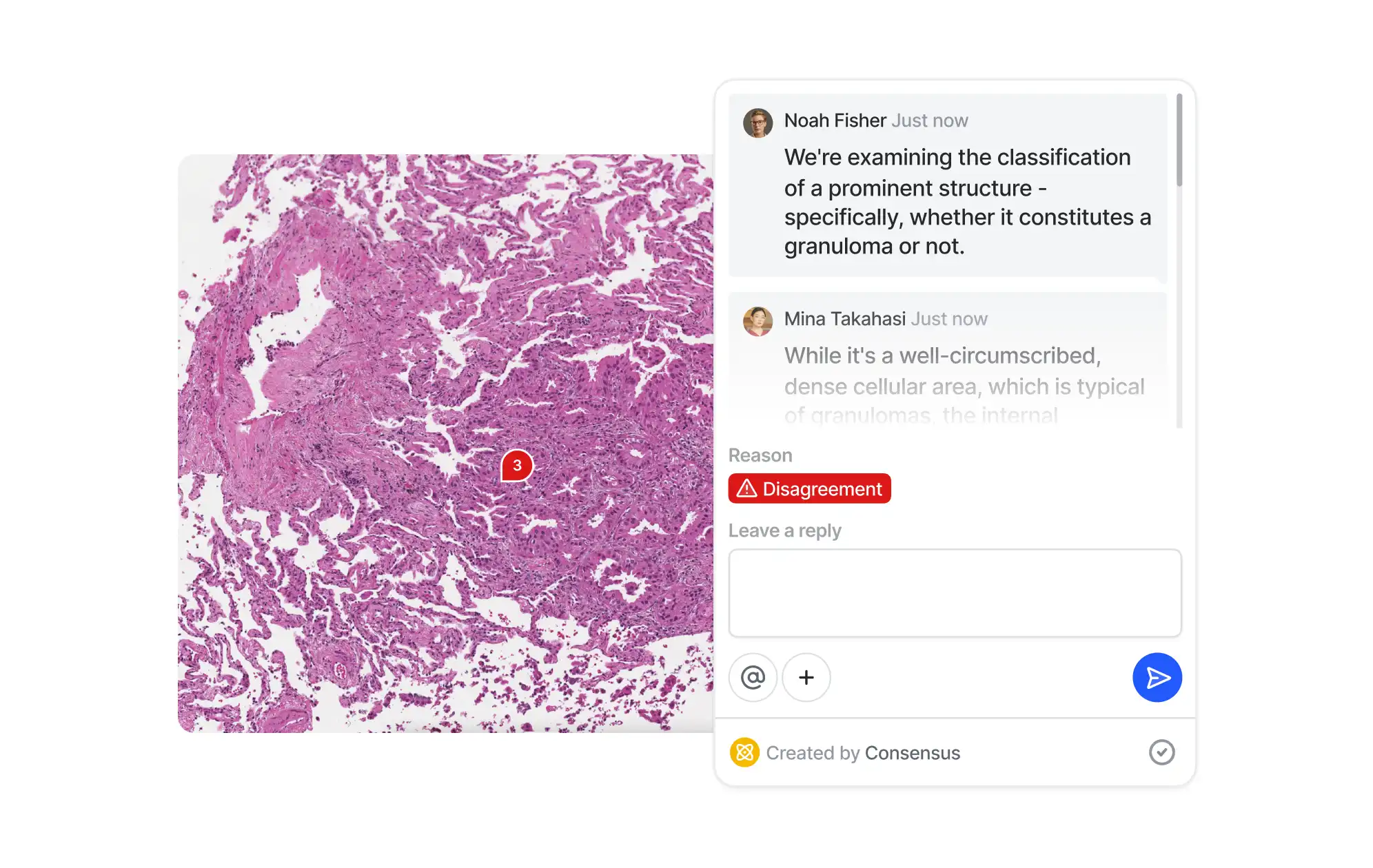

Consensus

Evaluate labelers

Data labeling services

Collaborate

Improve teamwork with real-time collaboration features. Ensure smooth communication between annotators, reviewers, and ML engineers to speed up assignments. Delegate tasks and track progress of multiple independent annotation projects.

Consensus

Evaluate labelers

Data labeling services

Collaborate

Improve teamwork with real-time collaboration features. Ensure smooth communication between annotators, reviewers, and ML engineers to speed up assignments. Delegate tasks and track progress of multiple independent annotation projects.

Consensus

Evaluate labelers

Data labeling services

Labeling services

Labeling services

Labeling services

Specialized data annotation

for modern AI challenges

Build vs Buy

Build vs Buy

Build vs Buy

Testimonials

Testimonials

Testimonials

Secure and trustworthy AI.

Here's what our customers say.

Secure and trustworthy AI.

Here's what our customers say.

Secure and trustworthy AI.

Here's what our customers say.

Security & Integrations

Security & Integrations

Connect your data with confidence.

Built for ML developers.

Connect your data with confidence. Built for ML developers.

Connect your data with confidence.

Built for ML developers.

Security & Integrations

Integrate with your toolstack

Integrate V7 with your existing ML infrastructure. Use your private cloud with major providers including AWS, Google Cloud, and Azure. Export annotations in formats compatible with popular frameworks like TensorFlow and PyTorch.

Integrate with your toolstack

Integrate V7 with your existing ML infrastructure. Use your private cloud with major providers including AWS, Google Cloud, and Azure. Export annotations in formats compatible with popular frameworks like TensorFlow and PyTorch.

Integrate with your toolstack

Integrate V7 with your existing ML infrastructure. Use your private cloud with major providers including AWS, Google Cloud, and Azure. Export annotations in formats compatible with popular frameworks like TensorFlow and PyTorch.

Built with security in mind

Benefit from SOC 2 Type II and HIPAA-compliant infrastructure. Set granular access controls and track all actions with detailed logs. Meet stringent security standards for industries like healthcare and finance.

Built with security in mind

Benefit from SOC 2 Type II and HIPAA-compliant infrastructure. Set granular access controls and track all actions with detailed logs. Meet stringent security standards for industries like healthcare and finance.

Built with security in mind

Benefit from SOC 2 Type II and HIPAA-compliant infrastructure. Set granular access controls and track all actions with detailed logs. Meet stringent security standards for industries like healthcare and finance.

Developer friendly API & SDK

V7 is built by developers for developers. Our tools make it easy to automate workflows, customize integrations, and extend V7's capabilities to fit your unique use cases. Enjoy clear documentation, code samples, and responsive support.

Developer friendly API & SDK

V7 is built by developers for developers. Our tools make it easy to automate workflows, customize integrations, and extend V7's capabilities to fit your unique use cases. Enjoy clear documentation, code samples, and responsive support.

Developer friendly API & SDK

V7 is built by developers for developers. Our tools make it easy to automate workflows, customize integrations, and extend V7's capabilities to fit your unique use cases. Enjoy clear documentation, code samples, and responsive support.

Built for scale

Handle projects of any size. Create multiple workspaces and invite users to collaborate. Manage and filter datasets with intuitive GUI dashboards. Set up custom views, add tags, and save advanced filtering conditions.

Built for scale

Handle projects of any size. Create multiple workspaces and invite users to collaborate. Manage and filter datasets with intuitive GUI dashboards. Set up custom views, add tags, and save advanced filtering conditions.

Built for scale

Handle projects of any size. Create multiple workspaces and invite users to collaborate. Manage and filter datasets with intuitive GUI dashboards. Set up custom views, add tags, and save advanced filtering conditions.

Next steps

Tell us more about your project.

Let's build a proof of concept.

Try our free tier or talk to one of our experts.

Next steps

Tell us more about your project.

Let's build a proof of concept.

Next steps

Tell us more about your project.

Let's build a proof of concept.

Try our free tier or talk to one of our experts.